Metallography and Optical Microscopy

Contact

Eng. Miguel Angel Esneider Alcalá

Phone: +52 (81) 11560805

Email: miguel.esneider@cimav.edu.mx

Metallography consists in preparation of specimens for microscopic examination followed by a study of their microstructure in relation to the physical and mechanical properties, as well as manufacture methods for the alloys. This technique, like many others, can be complemented by other studies, particularly microscopy and image analysis. The primary steps of a metallographic study are: cutting, mounting, grinding, polishing, etching and microstructural analysis.

CIMAV Monterrey has several equipments for sample preparation including metallographic and microstructural analysis.

Equipment available

- OLYMPUS metallographic microscope GX-51 and Olympus SZX-16 stereoscope

- Abrasive wheel cutter with LECO MSX300-A1

- Cutting precision diamond blade LECO VC-50

- Mounting press LECO PR-32

- Grinder/polisher LECO SS1000

- Belt grinder LECO BG-32

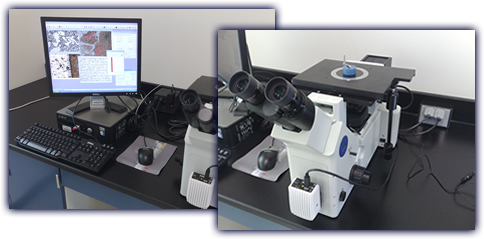

OLYMPUS metallographic microscopes GX-51 and Olympus SZX-16 stereoscope

It has the most advanced optical microscopes for use multidisciplinary materials science. We offer most of the lighting techniques used. It offers digital capture of images with high resolution micrographs, as well as rapid delivery of results. The technique is complemented by an image analysis software that includes several useful applications in metallurgy and other areas.

These teams have the following characteristics:

- In the metallographic microscope, resolution of 1000 increases, while the 115-stereographic increases.

- Lighting Techniques bright field, dark field, polarized light, differential interference contrast.

- 1.3 MP digital camera fitted with the image analysis software which comprises the most used applications in industry and research.

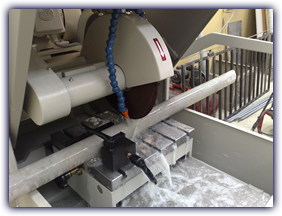

Abrasive wheel cutter with LECO MSX300-A1

Oscillating machine designed for sectioning large areas of ferrous and nonferrous alloys, hard materials, ceramics and composites. It has an adequate cooling system insuring that a cut does not affect the microstructure, as required for structural analysis.

This equipment has the following characteristics:

- 10 HP motor with an integrated mechanical brake

- Abrasive wheels up to diameter of 14 "

- Manual or pneumatic radial axis Z

- Work table made of stainless steel (dimensions: 45 X 40 cm) with T-slots equipped with accessories to clamp any room.

- The servomotor X-axis control and manual Y axis control

- Easy to operate control panel

- The forward speed cutter with automatic load maximizes cutting efficiency without altering the structure of the samples

- It has a side access port for the parts with large sections

External Services

- Metallographic specimen preparations.

- Measurements of grain size (equiaxed and elongated) according to standardized guidelines for a variety of materials (ferrous and nonferrous alloys).

- Standards-based measurements of porosity, secondary dendritic spacing, coating thickness measurements, phase percentages, percentages of nodules, measurements of uniformity, etc.

- Conventional cuts large pieces (approximately 40 x 40 cm), and pipe-length (> 1.5 m).

- Precise cuts small parts through the diamond blade.

- Microhardness measurements.

- Failure analysis.

- Tribology measurements (pin on disk technique).

Cutting precision diamond blade LECO VC-50

This equipment is ideal for precise cutting of ceramics, minerals, metals and electronic components with a maximum cross-section of 38 mm, ensuring minimal distortion and loss of the material. The selection of speed up to 500 RPM is continuously monitored and displayed by a tachometer. The equipment maintains the uniform cutting speed at different loads, using the disks 4 and 5 "in diameter.

This equipment has the following characteristics:

- Select variable speed of 0-500 RPM.

- precision micrometer in inches or millimeters to ensure proper positioning of the pieces.

- Weight slip for proper load application.

- Automatic if neglected for a long time.

- Features accessories for irregular samples.

Mounting press LECO PR-32

The equipment is semi-automatic and can process 2 mounts at once. The operation was performed in one cycle without operator intervention, the sequence is monitored by indicator lights, the pressure is maintained throughout the cycle. The mold is available for this equipment is 1.5"

This equipment has the following characteristics:

- Work with a pressure of ~ 4200 psi and 150-170 ° C

- Works with a wide range of assembly materials for different purposes, from Bakelite, epoxy, lucite, diallyl phthalate, diallyl phthalate with Cu for electron microscopy analysis

- If the material is sensitive to mounting conditions used in this equipment, you should opt for a cold mounting, we also have the accessories needed for its implementation.

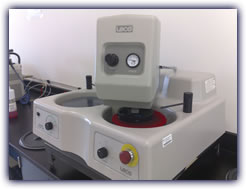

Grinder/polisher LECO SS1000

This team prepares the necessary mirror finish surface microscopy techniques, the grinding and polishing operation automatically does because it has a head equipped with fixtures which can hold several samples, the simultaneous preparation of several specimens ensures reproducibility the results obtained. Discs spin against clockwise, while the head does to please, this ensures proper surface preparation.

This equipment has the following characteristics:

- Rotation speed of 0-500 RPM disks.

- Programmable time of 30 s until an undetermined time.

- The head applies a pressure of 300 N.

- It has mounted fixtures for simultaneous sample preparation, 8 to 1 "diameter and 4 to 1.5 ".

- Variety of supplies for all types of materials.

Belt grinder LECO BG32

This equipment is ideal for any surface that will be subjected to another test where cleanliness and flatness are essential. You can work in wet or dry sandpaper and are interchangeable according to the material to work, the team has a recirculation system which provides an intense cooling which allows not to alter the microstructure of our material.

This equipment has the following characteristics:

- Powerful 1HP Motor which provides a superior metallographic preparation, and a simple design making it easy for the user operation.

- Excellent system of cleansing and tension of the sanding, the whole system is protected voltage which prevents the running of the sandpaper.

- The debris removal is done effectively due to the constant flow of water and the area of access for cleaning.

- It has security guards on both sides to protect the user all the time.

- Fairly robust, corrosion-resistant materials, aluminum exterior and stainless steel interior.

- Has a recirculation tank 20 gallons ensuring an intense cooling during operation.